Introduction

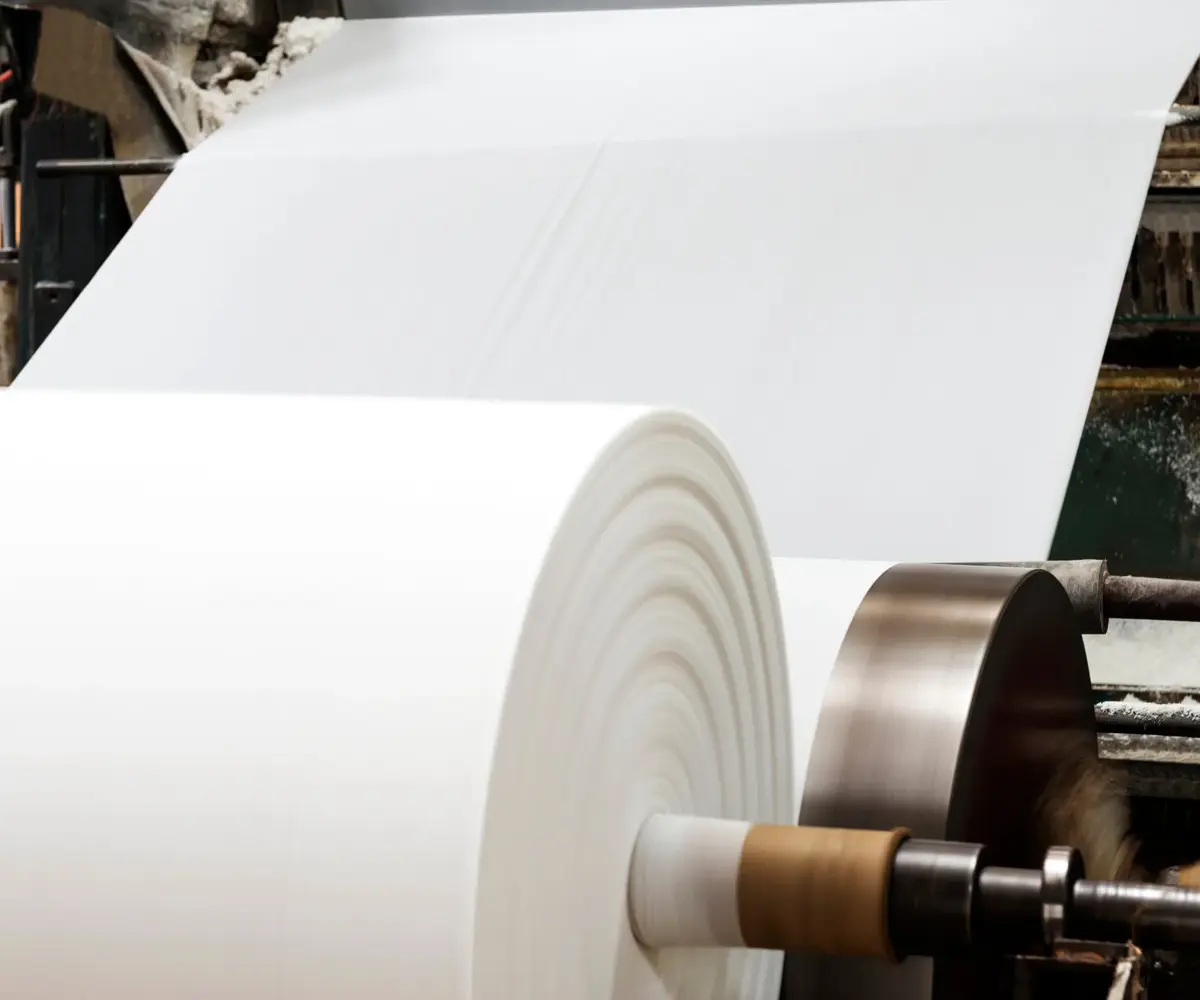

When sourcing paper, have you ever wondered what raw materials are used to make it? As a buyer for a printing company, packaging factory, or other paper-related business, understanding the raw materials in paper helps you evaluate quality, make better purchasing decisions, and communicate more effectively with suppliers. This article walks you through the main types of paper pulp and essential chemicals used in the papermaking process, so you can better understand how your paper goes from raw material to finished product.

Types of Raw Materials for Paper Making

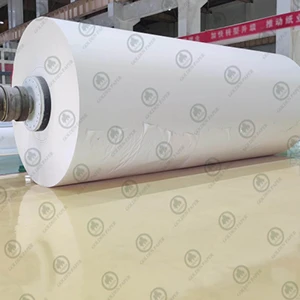

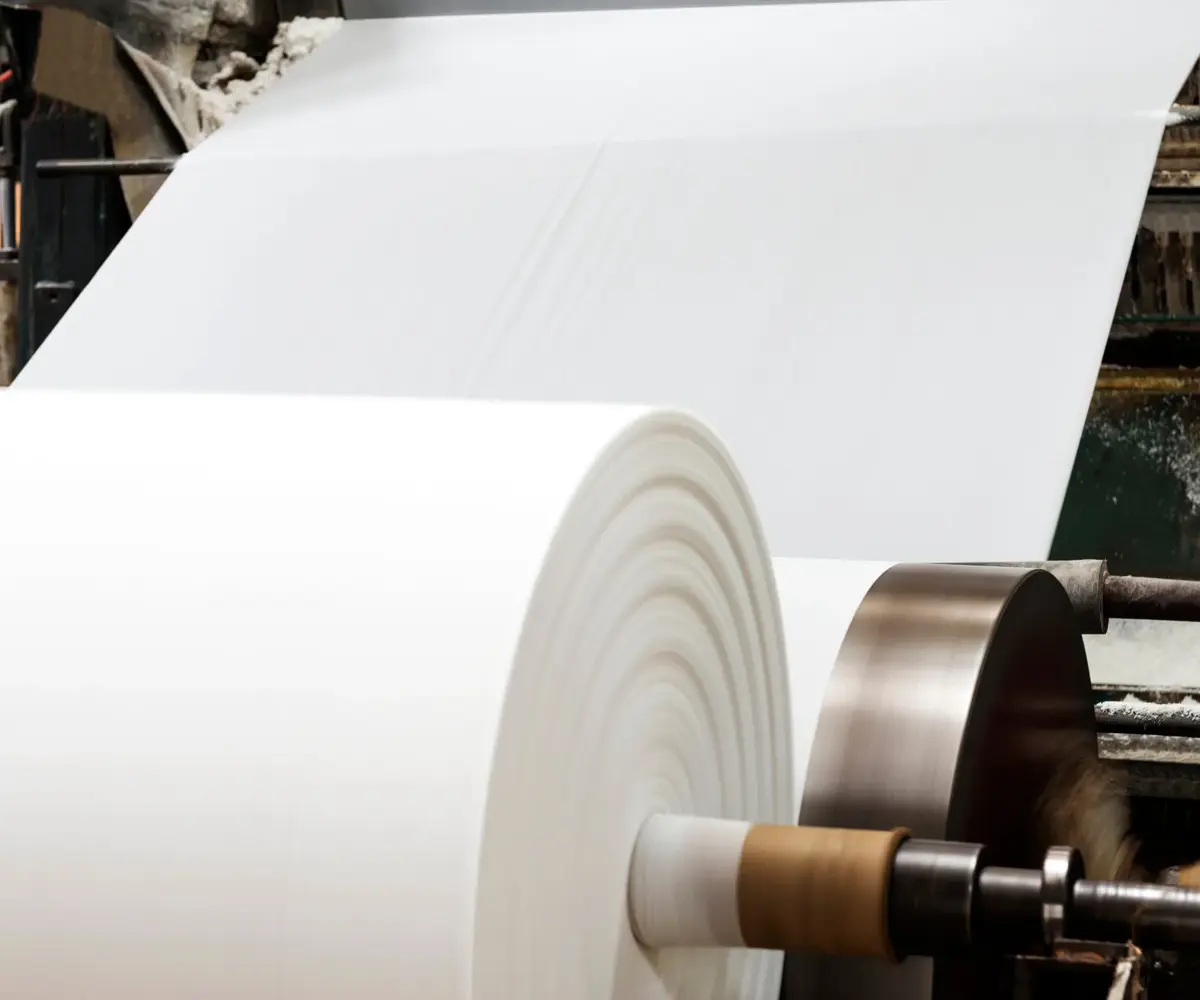

Wood Pulp

Wood pulp is the most common raw material for making paper today. It is derived from softwood or hardwood trees and processed in various ways, resulting in different types of pulp:

Chemical wood pulp is produced by cooking wood chips in an alkaline or acidic solution—typically using sodium hydroxide and sodium sulfide. This removes lignin while preserving cellulose, resulting in a pulp that produces strong, high-quality paper.

Mechanical wood pulp is made by physically grinding wood into fibers. It retains most of the lignin and is more affordable but has lower paper strength—ideal for newspapers and short-life publications.

Chemi-mechanical pulp combines chemical and mechanical processing. It partially removes lignin while retaining fiber length, offering a balance between performance and cost.

If you're sourcing paper that needs good whiteness, strength, and printability—such as coated paper or writing paper—chemical wood pulp is often your best option.

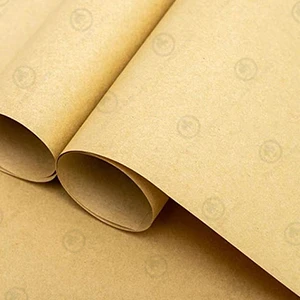

Non-Wood Pulp

In addition to wood-based pulp, paper can also be made from non-wood plant fibers. These include:

Grassy fibers such as straw, reed, bamboo, wheat straw, and sugarcane bagasse.

Bast fibers such as jute, hemp, mulberry bark, and paper mulberry. These are strong fibers often used in specialty or handmade papers.

Non-wood pulp is highly renewable and environmentally friendly. It is especially suited for companies looking for eco-conscious packaging materials or niche paper types like calligraphy paper or decorative sheets.

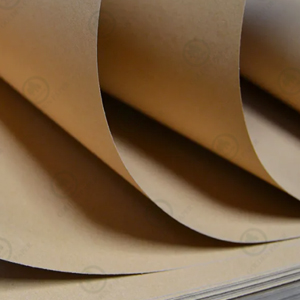

Recycled Paper Pulp

Also known as recycled fiber pulp, this material is increasingly used in the industry due to sustainability concerns. It's made by collecting used paper (books, cartons, printer offcuts), removing ink and impurities, and reprocessing the fibers into usable pulp. Recycled pulp are eco-friendly and cost-effective, because it can deduce deforestation and energy consumption and more affordable than virgin fiber pulp.

Although recycled pulp may have slightly weaker fiber strength due to previous processing, it is widely used for producing packaging paper, newsprint, and paperboard. With proper processing and additives, recycled paper pulp can meet a wide range of requirements.

Essential Chemicals Used in Papermaking

Papermaking isn’t just about pulp—it also involves a variety of chemical additives that enhance the paper’s functionality, appearance, and performance. Here's what to know:

Cooking Chemicals

To break down wood into fibers, the kraft pulping process (also known as the sulfate process) is commonly used. It relies on a solution called white liquor, primarily composed of sodium hydroxide and sodium sulfide. This dissolves lignin—the compound that binds fibers together—and releases the cellulose fibers for papermaking.

Kraft pulp is known for producing strong, high-performance paper and offers excellent chemical recovery rates, making it the most widely used method today.

Bleaching Agents

If the paper needs to be white—such as printing and cultural paper—the pulp must be bleached. This involves using oxidizing agents like: Oxygen (O₂), Ozone (O₃), Hydrogen peroxide (H₂O₂), Chlorine dioxide (ClO₂), Sodium hydroxide (NaOH). These chemicals break down residual lignin and colored substances while preserving the cellulose, resulting in brighter paper. Modern mills favor Elemental Chlorine-Free (ECF) or Totally Chlorine-Free (TCF) bleaching for lower environmental impact.

Fillers

To improve paper’s appearance and printability, paper fillers like calcium carbonate, kaolin clay, and talc are added to the pulp. These fillers can not only increase brightness and opacity, but also can improve surface smoothness of the paper. For example, titanium dioxide is used in Bible paper for enhanced whiteness and thinness. If you're purchasing paper for brochures, textbooks, or advertising prints, fillers are crucial for achieving image clarity and quality.

Sizing Agents

Sizing agents help the paper resist ink or moisture penetration. They directly affect how the paper interacts with ink during printing. Two main types are:

Internal sizing (e.g., AKD and ASA): Improves water resistance from within the sheet.

Surface sizing (e.g., starch): Enhances surface quality and print adhesion.

When sourcing inkjet or offset printing paper, proper sizing ensures clear print quality and minimal ink bleeding.

Strengtheners, Dyes & Other Additives

Depending on the final use of the paper, mills may add:

Strengthening agents: Cationic starch and polyacrylamide (PAM) improve dry or wet strength—vital for corrugated board or food-grade packaging.

Dyes and pigments: Used to produce colored papers or tinted sheets, like colored offset paper or Bible paper.

Other auxiliaries: Optical brighteners (enhance whiteness), retention aids (keep fillers in the sheet), defoamers, preservatives, and more.

These functional additives help customize the paper to your specific needs. If you’re looking for specialty papers, be sure to discuss additive use with your supplier.

Conclusion

Understanding the raw materials and chemical components behind papermaking gives you an edge as a professional buyer. Whether you’re sourcing cost-effective recycled board or high-white, well-sized cultural paper, knowing what goes into your product helps you make smarter, more efficient, and more sustainable decisions. Need technical specs or samples? Contact Golden Paper today—your trusted global supplier of high-quality printing and packaging paper.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id